Solar Panels for Farms and Businesses

According to the Department of Agriculture, electric bills are between 2% and 5% of a farm’s annual operating expenses, and costs rise on average 3.7% each year. With 2 out of every 25 farms in Minnesota shutting down or selling out between 2007 and 2012, smart farmers take every opportunity to maximize profits, meaning greater security for decades to come. That’s where solar panels for farms come in.

Farmers have greater access to renewable energy now than they will in the future thanks to the 30% federal tax credit (whose expiration begins in 2019), utility rebates (where applicable), and grants from the Department of Agriculture. Add to that accelerated depreciation, and solar panels for farms, which last 30 years or longer, pay for themselves in as little as 7 years or less. That means more than 23 years of free electricity for your farm.

Beyond the economic benefits, solar panels for farms empower farmers—the land’s original stewards—to produce reliable, zero-carbon electricity without moving parts and the maintenance of wind turbines. (Some turbine engines have to be replaced as often as every 3 years which takes both money and time.) Dairy and hog farms benefit the most because hot, windless days when sheds need cooling are the year’s peak production days for solar energy. Not only do the panels block some of the heat from entering the shed (not just speculation–this has been proven), they are generating extra electricity to offset what the cooling system is consuming.

Solar panels for farms and businesses are even better than for homes:

- Farms & businesses have bigger electric bills, and thus save more money.

- Farms & businesses have plenty of space to work with.

- Farms & businesses benefit from economies of scale.

- Farms & businesses have access to financial incentives, programs and depreciation.

On the other hand, each site presents its own obstacles. The good news is that, whatever building or property might need, you’re not the first to hit that road block, and the solar industry’s many innovative manufacturers have already developed a system to fit. Here are some of the elements that will determine your solar system design:

Ground-mount or roof-mount

Ground-mounted designs allow a system to produce the most energy by setting up in an ideal location at an ideal angle, regardless of any existing structures.

Ground-mounted solar panels for farms do need wire to be run for much greater distances. (We’ve trenched as far as 300 yards!) Long distances mean that the voltage on the line will drop, which is effectively losing electricity before you get to use it. The way to control the voltage drop is by carefully selecting the correct wire size for your system—the larger the wire, the less electricity is lost. However, larger wire is more expensive. Electrical code allows for up to 5% voltage drop (for most applications), but we have found that the sweet spot for most installations is around 2%; the increased cost for wiring is overcome by the increased production over the life of the system.

For roof-mounted systems, waterproofing is paramount. Flat roofs have waterproof membranes that can’t be penetrated; even when the penetrations are waterproofed, in almost all cases, it would void the warranty. That means the panels can’t be attached to the building itself, so they rely on weight to stay in position. Solar ballast systems incorporate ballast blocks—the same concrete blocks used in masonry and many other applications—and are engineered to withstand wind speeds far beyond what is required by building inspectors. This means that designing flat-roof systems requires the extra step of ensuring that the roof can handle the additional weight.

On the other hand, solar panels for farms can be attached to the building itself on pitched sheet-metal roofs, but they call for a unique set of waterproofing products because they can’t make use of the flashing products available for shingled roofs. For example, we prefer to use EcoFasten L-foot brackets; while all manufacturers include a rubber grommet for waterproofing, EcoFasten’s grommet is easily twice the thickness of their competitors’. Paired with the GeoCell (a 50-year roofing sealant) used to fill the pilot hole we drill, our L-foot installations are more than waterproof. In fact, we’ve NEVER had a roof leak!

Standing-seam metal roofs don’t have any waterproofing requirements, because the system can be held on by hardware that clamps onto the seam. We use the set-screw clamps by manufacturer S-5!; even their mini clamp with a single set screw outperformed the inspector’s requirements by a factor of four! In almost all cases, the equipment holding the panels to the roof is stronger than the equipment holding the roof onto the building.

Assessing the electrical system

Commercial and agricultural electrical systems are far more complex than residential systems. Just one of the requirements to consider is whether the site is set up for single-phase or three-phase current. Adding to the complexity, commercial and agricultural sites have often added buildings or major equipment, and not all electrical contractors leave clear notes about how the system was adapted.

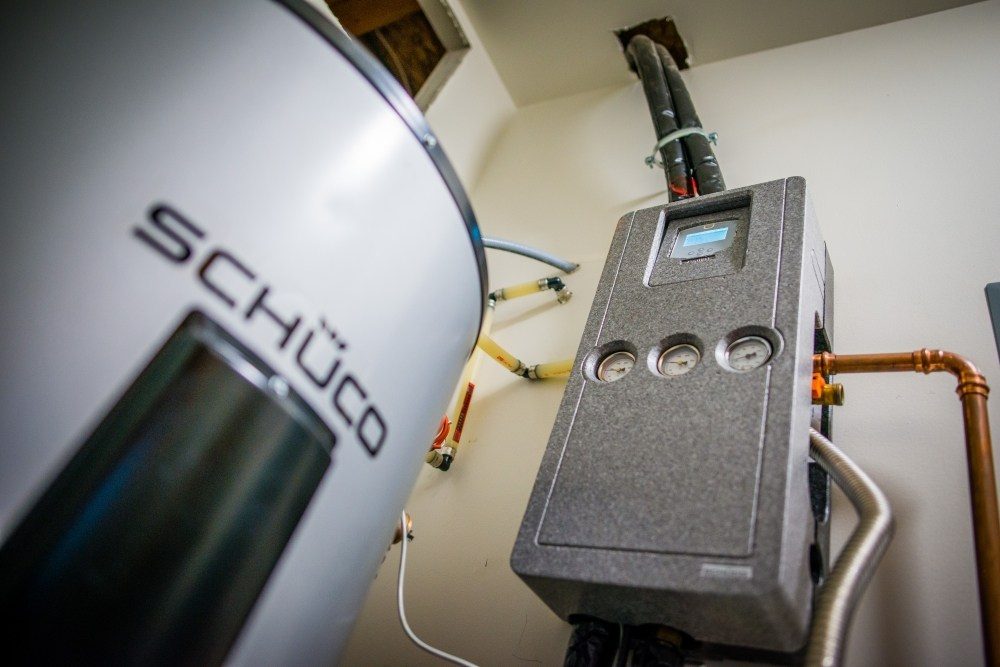

We often install other electrical equipment like CT cabinets (a current transformer is used when the current coming into a site is bigger than a single meter can handle), breaker panels, switch gears and tap boxes. For example, it’s easy to wire the system in a way that overloads the bus bar, which is the spine of the breaker panel where current is running up and down between the main breaker into the sub-breakers. If done incorrectly, the bus bar will get hot spots, which can cause fires or burn out the bus bar. In that case, not only is your solar down, but your entire facility is without electricity. We once installed a system on a facility that already had a renewable energy system but with the breaker in the wrong position and an oversized the bus bar. On a day with a lot of electricity generation, they were vulnerable to burnout and fire. Fortunately, we can correct most or all of those kinds of problems when doing our work.

Backup generators

Most farms and commercial settings have back-up generators, so we have extensive experience pairing solar panels for farms with back-up power. Generators work well with solar power if set up correctly. But if not, it can force the solar inverter to continue sending power into the grid while linemen are doing repairs—a potentially lethal mistake. Even if accidents are avoided, connecting the generator and solar system incorrectly will void equipment warranties—a major loss considering that the electronics will have at least a 10 – 15-year warranty, and the solar panels will have a 25-year warranty. If you don’t already have a generator, we can install that too, so you will know it was done right.

Maintenance

Farmers choose solar because of it takes care of itself. Wind turbine engines—another high-production, environmentally friendly energy source—need to be replaced as often as every 3 years, which not only means writing big checks, but also hiring a crew and trucking equipment onto the field. On the other hand, the most maintenance your solar array will require is an occasional rinse—maybe once a year during harvest—but only if there hasn’t been rain to remove dust and debris.

Solar Panels for Farms & Businesses: Summary

Your farm’s terrain and building materials will influence your solar design as much as the amount of electricity you use. The design has to correctly account for the existing electrical system and equipment and generator loads. An experienced contractor like Solar Connection will navigate these complexities while also processing the paperwork for you to take advantage of all the renewable energy incentives available. When your solar installation is done, it’s done, and you can focus your energy on running a profitable business.